Why Should Manufacturers Replace Manual Scheduling with AI-Driven Solutions?

In the ever-evolving world of manufacturing, In the world that sometimes develops, production efficiency is the basis for profitability and competition. Nevertheless, many manufacturers are still dependent on outdated, manual planning methods that cannot live at the speed of modern production requirements. With market fluctuations, complex supply chains and only pushing for the delivery of time periods, manual planning has become a bottleneck instead of a development tool.

AI-driven manufacturing scheduling offers a smart, sharp and more accurate way to manage the production limit. By utiliZing AI agents for production scheduling, manufacturers can transfer to active adaptation from reactive problem solutions to reduce the deficiency, reduce shutdowns and increase production without compromising on quality.

In this article we will find out why manual planning with AI-driven solutions is not just a technical upgrade-it is a strategic requirement.

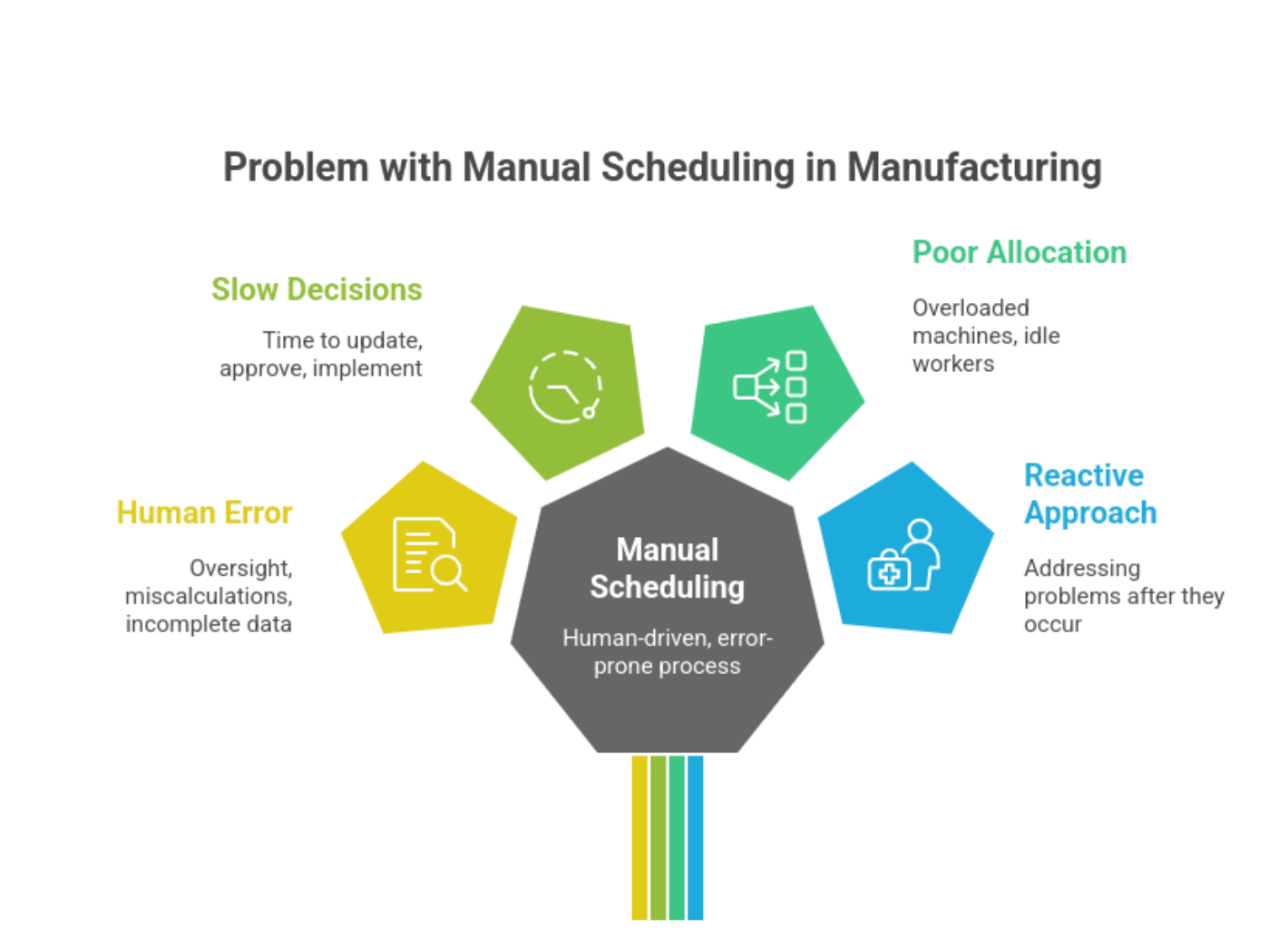

The Problem with Manual Scheduling in Manufacturing

- Human Error and Inaccuracy

Manual scheduling depends a lot on human entrance, spreadsheets or outdated ERP modules. This makes the plan prone to oversight, miscalculations, and incomplete data processing - problems that can lead to delayed and increased costs. - Slow Decision-Making

In a fast-paced manufacturing environment, production schemes often need to change rapidly due to problems with the supply chain, the machine's breakdown or sudden demand change. Manual scheduling requires significant times to slow down, update, approve and implement the entire process. - Poor Resource Allocation

Without real -time data integration, machine capacity for manual planners, the availability of workforce, distribution of raw materials and simultaneous priority for priority together. The result? Overloaded machines, idle workers, and wasted materials. - Reactive, Not Proactive

Manual scheduling is generally reactive - detecting problems after their existence - they can predict the AI solution barriers before they occur.

What Is AI-Driven Manufacturing Scheduling?

AI-driven manufacturing scheduling uses machine learning algorithms, future statement analysis and intelligent automation to create a real-time production program.

AI agents for production scheduling are specialized software tools designed to:

- Analyze real-time production data

- Predict resource requirements

- Adjust schedules instantly based on changing conditions

- Balance workloads in machines and teams

The main difference is that optimization is an AI operated system, facing the static manual plan develops with the production process.

Why Manufacturers Should Switch to AI Scheduling?

The shift from manual to AI-driven scheduling is more than just adopting a new tool - where this production is controlled is a change. Why should manufacturers now exchange to switch here.

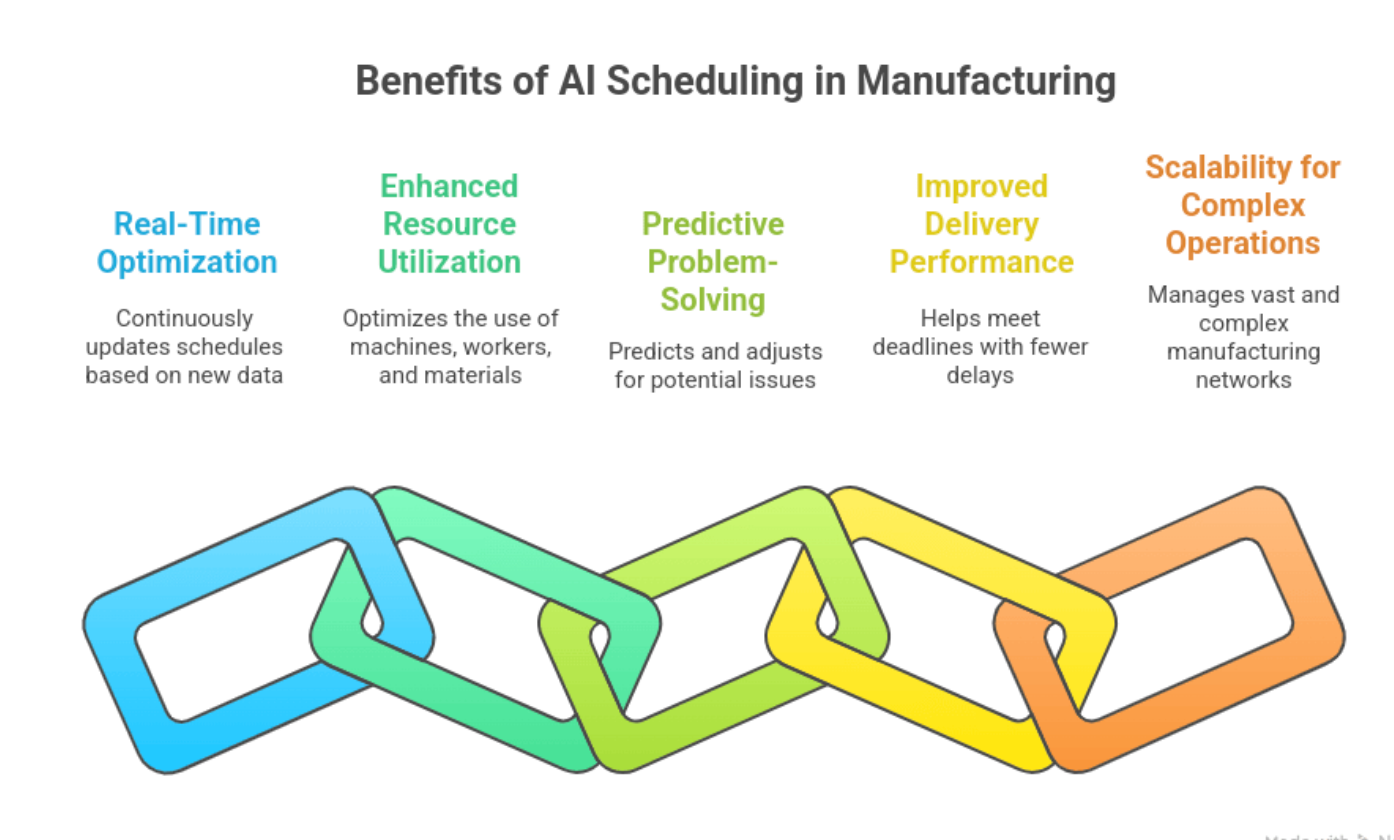

1. Real-Time Optimization

With the AI solutions for production planning,, the plan is constantly updated when new data is coming - whether it is the supply delay, the machine maintenance warning or an immediate customer order. This ensures maximum uptime and minimum disruption.

Example: If a CNC machine stops unexpectedly, an AI system can immediately develop the workload for machines available without waiting for human intervention.

2. Enhanced Resource Utilization

AI in production automation ensures that each machine, work and material is better used. Algorithms calculate the most effective use of resources while avoiding obstacles.

Key benefits: Low waste, better production and better management of the workforce.

3. Predictive Problem-Solving

Instead of responding to the delay, AI production scheduling predicts potential problems - such as storage shortages or shutdown in the machine - and adjusts the plans before the problems arise.

Example: If the delivery of raw materials is expected to be late, AI can reorganize production functions to focus on jobs that do not require material until they arrive.

4. Better delivery performance

By balancing and using the production load, AI helps the scheduling manufacturers to complete the tight time limit with a low delay - promotes customer satisfaction and competitive advantage.

5. Scalability for Complex Operations

For manufacturers managing multiple production lines, facilities, or global operations, manual scheduling simply can’t keep up. AI agent development services can create scalable scheduling systems capable of managing vast and complex manufacturing networks with ease.

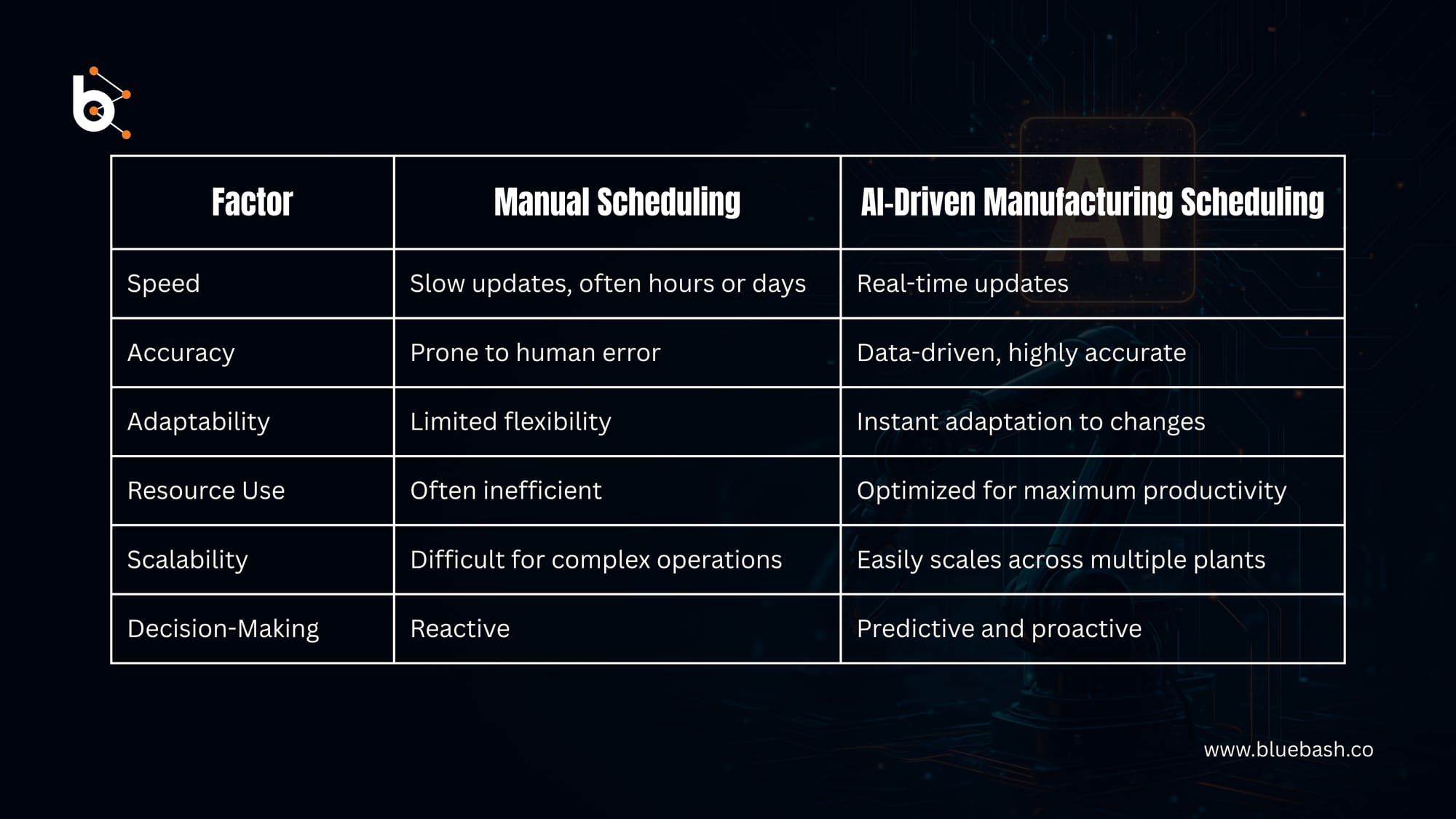

Manual vs AI Scheduling in Manufacturing: A Direct Comparison

How AI Agents for Production Scheduling Work ?

- Data Collection: AI agents collect real-time data from IoT sensor, ERP system, supply chain input and work management equipment.

- Analysis and Forecasting - Machine learning models process historical and relevant data to predict the needs of production and detect potential bottlenecks.

- Optimization - AI algorithms create the most effective plan based on available resources, time constraints and priorities.

- Dynamic Adjustment - if conditions change, reorganize AI immediately and update the schedule, and ensure minimal downtime.

Key Benefits of AI Solutions for Production Planning

- Reduced Downtime

AI reduces unplanned shutdown by continuously adjusting the schedule when there is maintenance or breakdown. - Lower Operational Costs

AI reduces energy consumption, labor costs and waste by optimizing the resource allocation. - Better Demand Matching

AI produces output carefully adjusts production with the demand for the real market, reduces overproduction and extra inventory. - Higher Employee Productivity

With AI in manufacturing automation, supervisors spend less time on short time programs and more time improvement procedures.

Real-World Example: AI Scheduling in Action

A mid-sized automotive parts manufacturer had a delay in continuous distribution due to inconsistent raw material supply and machine distribution to the manufacturer. AI-driven manufacturing scheduling, they achieved:

- 25% increase in on-time deliveries

- 15% reduction in overtime costs

- 20% drop in production idle tim

The AI system automatically rescheduled production based on real-time supplier updates and predictable maintenance alerts-some manual scheduling can never effectively skill.

Addressing Concerns About Switching to AI Scheduling

While the benefits are obvious, some manufacturers hesitate due to misconceptions:

“AI scheduling is too expensive.”

Early implementation costs are expanded beyond better efficiency, low shutdown and long-term savings from better resource management.

“It’s too complex for our team.”

Modern AI agent development services ensure intuitive dashboards and minimal training requirements, making the transition smooth.

"We will lose control of our schedule."

AI does not take place to make human decisions-it increases it by providing better data and fast adjustment.

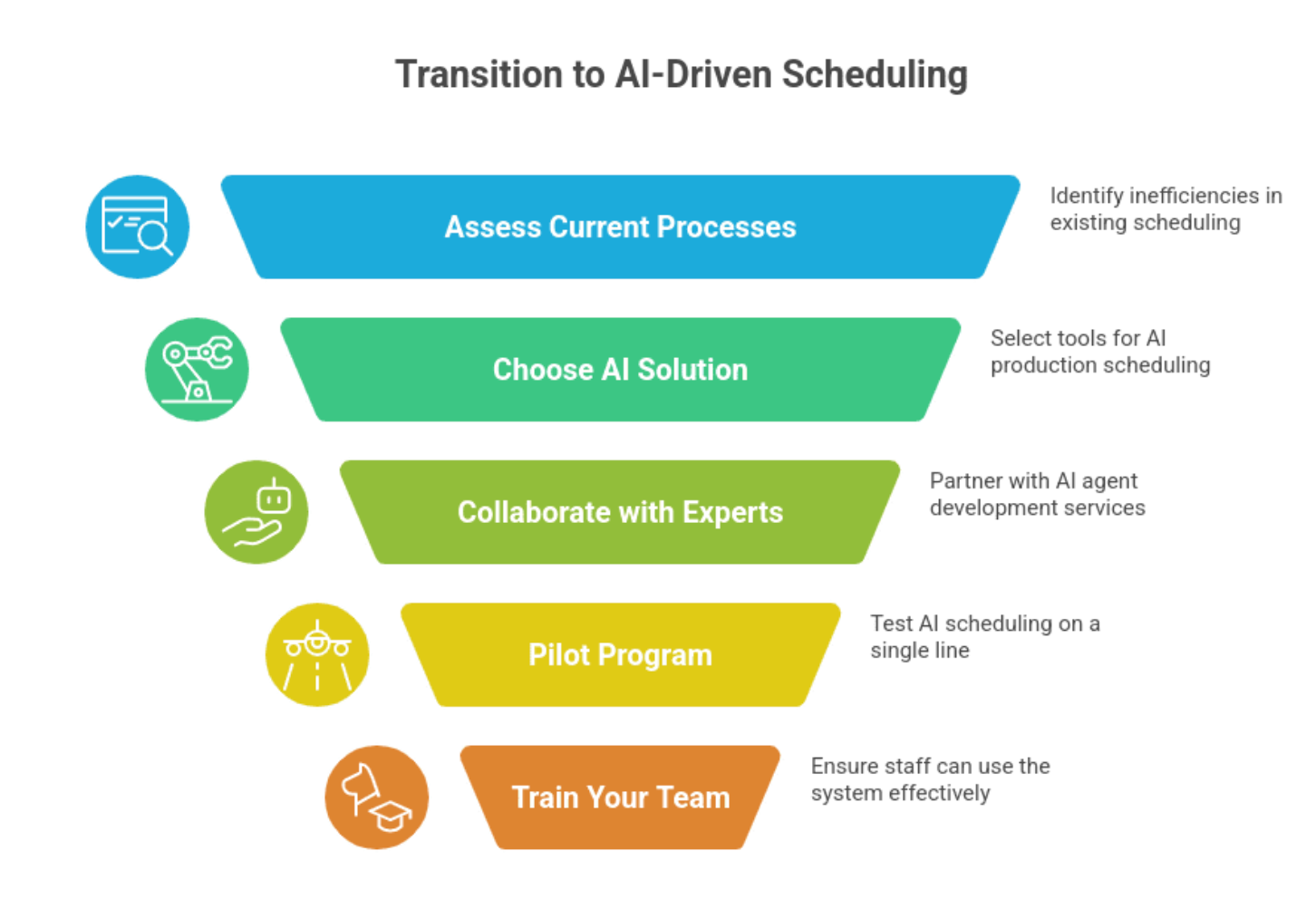

Steps to Transition from Manual to AI-Driven Scheduling

- Assess Current Processes - identify disabilities in your existing planning.

- Choose the Right AI Solution -Look for tools designed for AI production scheduling that is integrated with your existing ERP or MES system.

- Collaborate with Expert - Partner with a provider of AI agent Development Service that understands production workflow.

- Start with a Pilot Program - Test AI planning on a single production line before scaling through the entire system.

- Train Your Team- make sure your staff know how to explain the AI recommendations and use the system effectively.

Why Choose Bluebash for AI-Driven Production Scheduling ?

Partnership with Bluebash means working with a team that understands both production challenges and advanced AI solutions

.- Proven Specialization - Experience in distributing the AI agent Development Services for complex workflows.

- Custom-Built Solutions -We designer AI-driven manufacturing scheduling tools that are initially integrated with your existing ERP/MES system.

- Scalable & Future-Ready: AI agents adapt as production requirements, which ensure long-lasting ROIs.

- End-to-End Support: rom consultation to deployment and ongoing optimization, we are at each stage with you.

With Bluebash, manufacturers gain a partner committed to turning production scheduling into a strategic advantage.

Final Thoughts: Partnering for AI Success

The future of manufacturing is of those who embrace AI solutions for production planning and AI in manufacturing automation. By participating with an experienced providers of AI agent Development Service, manufacturers can use the system to fit their specific workflows - a smooth transition and centre for maximum ROI.

At Bluebash, we specialize in the production of intelligent AI agents for production scheduling that help manufacturers to streamline operations, reduce waste and meet customer requirements with accuracy. It is time to replace manual scheduling is now -and with the right AI partner your production floor can run completely like a tuned machine.

FAQ's

- What is AI-driven manufacturing scheduling?

It’s the use of machine learning and automation to create, optimize, and adjust production schedules in real time, ensuring maximum efficiency and minimal downtime. - How is AI scheduling better than manual scheduling?

AI scheduling offers real-time updates, predictive problem-solving, and optimal resource allocation, unlike manual methods that are slower and prone to errors. - Is AI production scheduling expensive to implement?

While there’s an initial cost, the long-term savings from reduced downtime, better resource use, and increased output far outweigh the investment. - Can AI integrate with our existing manufacturing systems?

Yes. AI agents for production scheduling can integrate seamlessly with ERP, MES, and IoT systems for smooth adoption. - Will AI scheduling replace human decision-making?

No—AI supports managers with accurate, data-driven insights, allowing them to make faster and better decisions