How Are Manufacturers Using AI Agents to Cut Wasted Space and Cost?

Manufacturers today are facing a difficult balance action - by controlling operating costs, maximizing efficiency and using space carefully, improving the customer's increasing demand. Traditional methods for factory layout planning and optimization can only go so far. With the emergence of AI agents for factory layout optimization, manufacturers now have smart tools to reduce waste, increase productivity and cut unnecessary costs.

In this article we will find out how the AI factory layout planning is the formation of manufacturing operations, how it is linked to lean principles, and further thinking companies use these techniques to prove their business.

The Growing Challenge of Space and Cost in Manufacturing

Factory space is some of the most expensive real estate in the industrial world. Poorly designed layouts lead to:

- Bottlenecks in production lines

- Excessive worker or material movement

- Idle machinery consuming valuable floor space

- Inefficiently used storage areas

Meanwhile, global competition and economic pressure manufacturers are forced to reduce costs without the relief of quality. This is where AI in factory automation and optimization come in. Instead of fully trusting human expertise, manufacturers now use AI factory optimization solutions, which maximize the efficiency of simulating, analyzing and recommending changes.

What Are AI Agents for Factory Layout Optimization?

An AI agent for factory layout optimization is essentially a digital assistant trained to evaluate and improve factory design. These agents use machine learning, simulation, and optimization algorithms to:

- Map current layouts

- Detect wasted space

- Suggest new equipment arrangements

- Estimates the impact on cost, security and production speed

Unlike even planning tools, AI agents are adaptive - they learn from external factors such as continuous historical data, live production metrics and external factors like supply chain fluctuations. As a result, the layout plan develops in a ongoing, data-driven process instead of a one-time exercise.

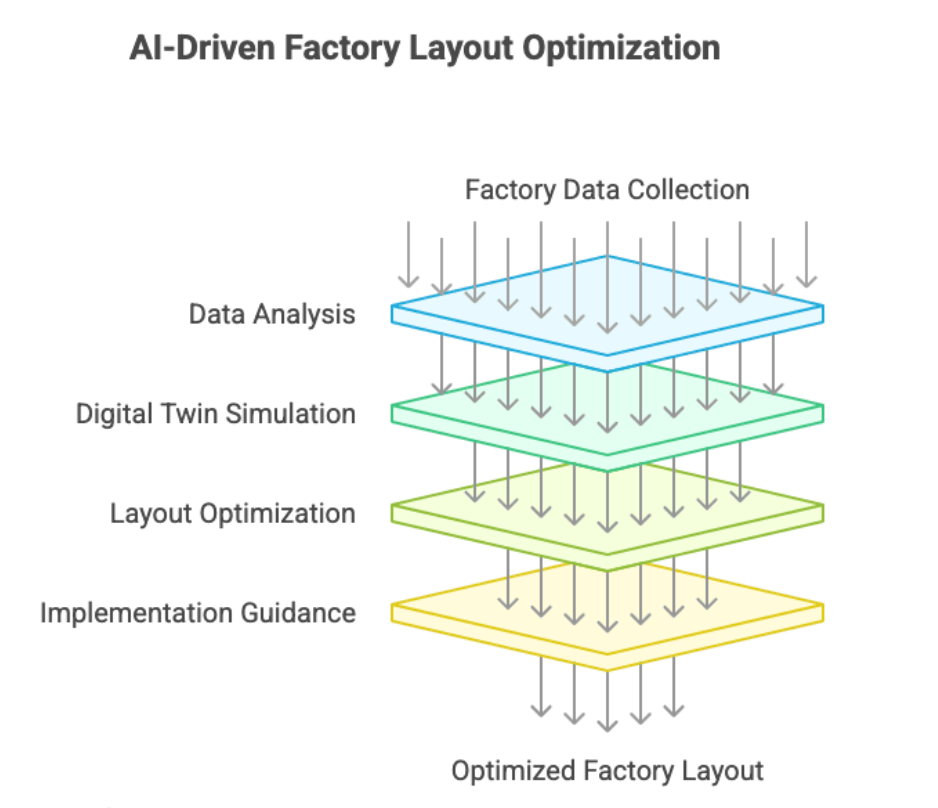

How AI Factory Layout Planning Works?

- Data Collection – IoT sensors, production logs, and machine performance data are gathered.

- Simulation – AI builds digital twins of the factory floor to test new layouts virtually.

- Optimization – Algorithms identify the most efficient setup with minimal wasted movement or space.

- Implementation Guidance – AI agents recommend actionable changes (e.g., “relocating Machine A closer to Machine B reduces transit time by 12%”).

This prevents costly trial-and-error changes in the physical environment.

Benefits of AI Agents for Factory Layout Optimization

- Space Efficiency - Reduces underutilized floor space, opening room for new lines or safer pathways.

- Cost reduction - Adapted design of low material handling costs, reduces idle time and supports AI in manufacturing cost reduction strategies.

- Increased Productivity – Cuts bottlenecks so workers and machines focus on high-value tasks.

- Flexibility - when demand is changing or new technologies lighter setup.

- Stability - Energy reduces waste, extra storage and disability.

Real-World Applications of AI Factory Optimization Solutions

- Automotive Manufacturing

AI-driven assembly line redistributed material helps to reduce handling and speed up production. - Electronics Production

Factories optimize floor plans to add more production lines to limited space that ensures compliance and safety. - Food & Beverage Industry

AI ensures cold storage and packaging stations are arranged for maximum energy efficiency and freshness retention.

AI for Waste Reduction in Manufacturing

Waste goes beyond scrap—it includes wasted time, energy, labor, and space. AI for waste reduction in manufacturing aligns with lean principles by eliminating non-value-added activities:

- Transport Waste: Reduces unnecessary material movement.

- Inventory Waste: Predicts demand to avoid overstocking.

- Motion Waste: Minimizes worker travel distances.

- Overproduction Waste: Prevents idle or unnecessary output.

This is how AI agents reduce waste in lean manufacturing by detecting inefficiencies and recommending improvements that traditional audits often miss.

Why AI in Manufacturing Cost Reduction Matters Now?

Manufacturing is under immense pressure to reduce costs while innovating. AI factory optimization solutions help achieve this by:

- Accelerating Time-to-Market – Faster production cycles from smoother workflows.

- Lowering Labor Costs – Reducing wasted effort.

- Reducing Overhead – More efficient space means lower energy and facility costs.

AI ensures manufacturers prevent cost leaks instead of merely reacting to them.

Why Choose Bluebash for AI Factory Layout Optimization?

The success of AI agents for factory layout optimization depends on the right partner. Here’s why manufacturers choose Bluebash:

- Custom Solutions: Tailored to your production setup.

- Proven Expertise: AI factory set-up plan and record strong tracks in automation.

- End-to-End Support: Guidance from evaluation through deployment.

- ROI Focused: Every improvement delivers measurable cost savings.

- Scalable and Future-Ready: Solutions evolve with your factory’s growth.

With Bluebash, your factory floor becomes smarter, leaner, and more cost-efficient.

The Future of AI Factory Layout Planning

Expect to see:

- Real-Time Optimization – Layouts that shift instantly with demand.

- Collaborative AI Agents – Systems working together across plants.

- Supply Chain Integration – Layout planning aligned with logistics.

The future factory will be continuously optimized, not periodically redesigned.

Conclusion: Smarter Factories Start with AI

The real question is no longer “Should manufacturers use AI?” but “How soon can they integrate it?”

By embracing AI factory optimization solutions, manufacturers achieve:

- Reduced waste and cost

- Optimized use of space

- Safer, more efficient workflows

- Scalable lean practices

In short, AI in factory automation transforms inefficiencies into competitive advantages. Now, Manufacturers will not only cut today's costs, but will also prove their business in the future.

As your AI agent development partner with Bluebash, you get smarter layout, sustainable growth and long-lasting innovation to stay ahead of the curve.

FAQ's

- How are manufacturers using AI agents to cut wasted space?

Manufacturers use AI agents to study factory layouts, find underused areas, and suggest better equipment placement. This reduces bottlenecks and opens up floor space. - Can AI really reduce manufacturing costs?

Yes. AI cuts costs by lowering idle time, reducing material movement, saving energy, and improving space efficiency across the factory floor. - What is AI factory layout optimization?

AI factory layout optimization uses digital twins, simulations, and smart algorithms to improve layouts. It helps manufacturers increase productivity and reduce costs. - How does AI support lean manufacturing?

AI removes non-value-added activities like excess motion, transport, and overproduction. This makes processes leaner and more efficient in real time.

- Why should manufacturers choose Bluebash for AI layout planning?

Bluebash provides tailored AI solutions with proven results, end-to-end support, and measurable ROI. Their scalable approach ensures long-term efficiency gains.