How to Implement AI Packaging Optimization in Manufacturing Operations?

Quick Summary

AI Packaging Optimization is transforming how manufacturers design, produce, and manage packaging. By integrating AI agents for packaging optimization, companies can minimize waste, enhance efficiency, and reduce costs — all while improving sustainability and customer satisfaction. This guide explains how to implement AI packaging optimization in manufacturing operations, what tools and technologies to consider, and how working with an AI agents development company like Bluebash can streamline your journey to intelligent packaging efficiency.

Introduction: The Rise of AI in Manufacturing Operations

Modern manufacturing thrives on precision, sustainability, and efficiency — and packaging plays a crucial role in all three. From material selection to logistics, packaging impacts cost, waste, and overall operational flow. However, traditional packaging design and management rely heavily on manual estimations and trial-and-error processes.

With AI in manufacturing operations, companies are now harnessing data-driven insights to automate and optimize packaging workflows. AI-powered packaging optimization uses machine learning, computer vision, and predictive analytics to determine the best packaging configurations, reduce material usage, and cut transportation costs — all while maintaining product safety and compliance.

Understanding AI Packaging Optimization

AI packaging optimization involves using advanced algorithms and AI agents for packaging optimization to analyze packaging processes end-to-end. These agents continuously learn from data such as product dimensions, materials, supply chain logistics, and even customer feedback to make packaging smarter and more sustainable.

Key Functions of AI Agents in Packaging Optimization

- Material Utilization Analysis:

AI evaluates various packaging materials to suggest the most cost-effective and eco-friendly options. - Design Optimization:

Machine learning models simulate thousands of design variations to find the perfect balance between durability and material efficiency. - Logistics Integration:

Packaging AI systems sync with shipping data to design packages that minimize space waste, improving container utilization and reducing freight costs. - Predictive Maintenance:

AI monitors packaging machinery for wear and tear, predicting failures before they occur. - Sustainability Tracking:

AI agents help manufacturers meet sustainability goals by tracking carbon footprints and material recycling metrics.

By implementing packaging optimization using AI, manufacturers not only streamline production but also create packaging that is functional, sustainable, and cost-effective.

Why Manufacturers Are Turning to AI-Powered Packaging Optimization ?

Global competition, rising material costs, and strict sustainability mandates are driving manufacturers to rethink how they manage packaging. Traditional manual optimization methods are slow and prone to human error. In contrast, AI-powered packaging optimization enables real-time decision-making and continuous improvement through automation.

Benefits of AI in Packaging Optimization

- Reduced Material Waste: AI algorithms calculate the minimal material required per product, leading to measurable cost savings.

- Enhanced Speed: Automated packaging design and testing dramatically cut lead times.

- Quality Consistency: Computer vision ensures packaging integrity and uniformity across production lines.

- Sustainability: AI identifies opportunities for biodegradable or recyclable materials without compromising product protection.

- Cost Efficiency: Optimized designs mean fewer damaged goods and better shipping economics.

For instance, an electronics manufacturer using AI packaging systems saw a 15% reduction in packaging material and 20% faster packing times after integrating AI-driven optimization models.

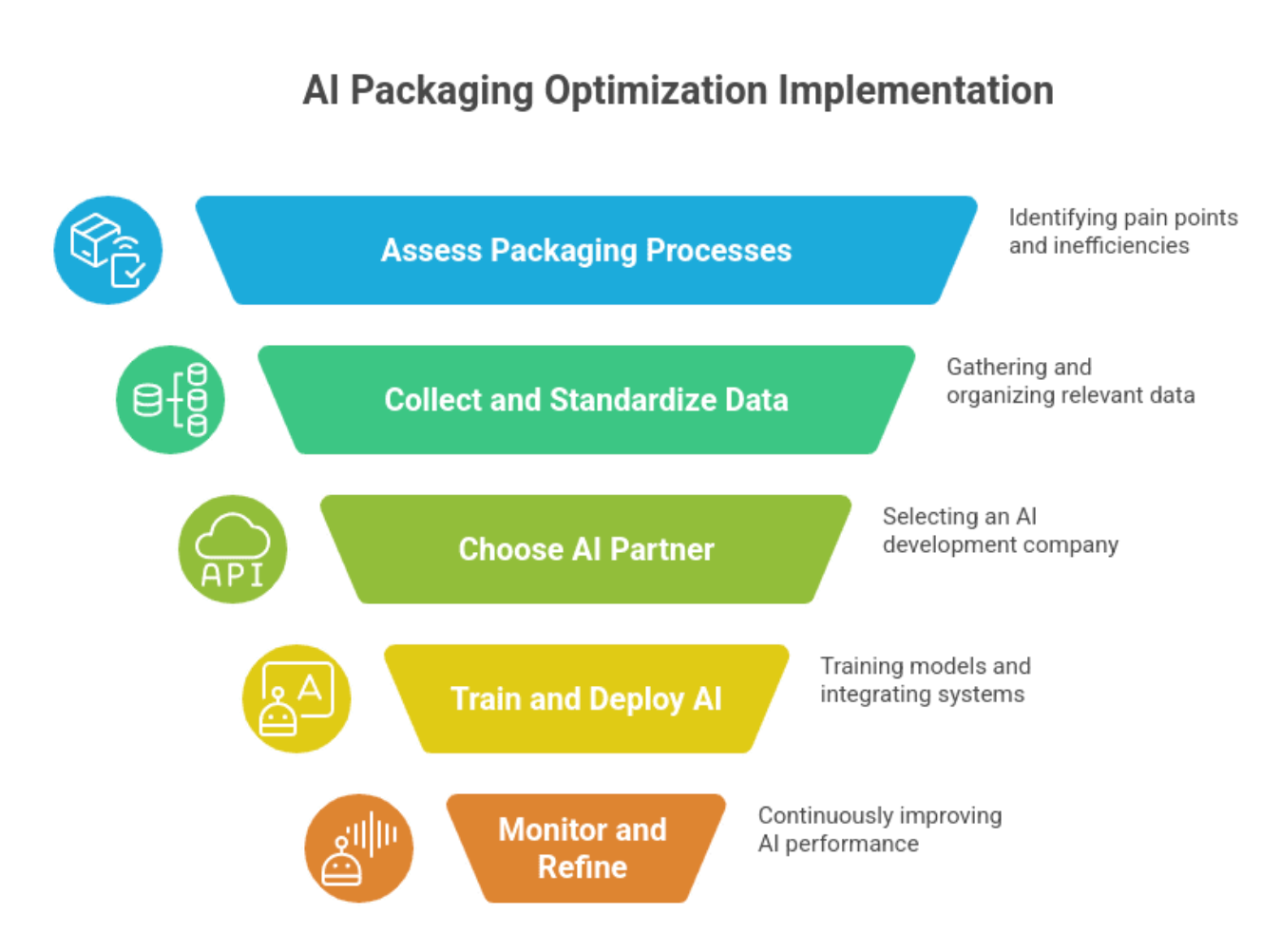

How to Implement AI Packaging Optimization in Manufacturing?

Implementing AI packaging optimization requires a structured approach — from assessing your current operations to deploying intelligent AI agents that seamlessly integrate with existing workflows.

Step 1: Assess Current Packaging Processes

Begin by evaluating your current packaging setup — materials, machine operations, waste percentages, and design bottlenecks. Identify key pain points such as excessive waste, high costs, or packaging line inefficiencies. This baseline data is essential for training your AI models effectively.

Example:

If you notice high material wastage in carton cutting, AI can analyze cutting patterns to reduce offcuts and optimize sheet layouts.

Step 2: Collect and Standardize Data

AI thrives on data. Collect information from sensors, ERP systems, logistics software, and production lines. Standardize this data format so your AI agents for packaging optimization can easily interpret and learn from it.

Important data points include:

- Product size and weight

- Packaging materials and cost per unit

- Transportation dimensions

- Machine speed and energy usage

- Defect and return rates

A centralized database helps the AI model find patterns across operations — for instance, which product categories cause the most packaging waste.

Step 3: Choose the Right AI Agents Development Company

Partnering with an AI agents development company ensures that your implementation strategy aligns with your manufacturing goals. Experts in AI in manufacturing operations can tailor algorithms to your unique production environment and integrate them with legacy systems.

Bluebash, for example, builds custom AI agents for packaging optimization that connect with PLCs, MES, and ERP systems — ensuring real-time data exchange and actionable insights.

Step 4: Train and Deploy AI Models

Once data is ready, AI models can be trained to understand your packaging parameters. Machine learning algorithms simulate multiple packaging configurations and test them virtually before deploying them on actual lines.

These simulations can predict:

- Optimal packaging dimensions

- Best material-to-product ratio

- Load-bearing capacity

- Shipping efficiency

Once validated, the AI-powered packaging optimization system is deployed to production. This phase often includes integration with robotic systems or automated packaging machinery.

Step 5: Monitor, Refine, and Scale

AI systems continuously learn. As new data comes in, your AI agents for packaging optimization refine their predictions and recommendations. Manufacturers can monitor metrics like material savings, time efficiency, and defect rates to measure ROI.

When proven successful, scale AI implementation across multiple plants or product categories to maximize benefits.

Real-World Use Cases of Packaging Optimization Using AI

- Food and Beverage Manufacturing

AI adjusts packaging thickness based on moisture, temperature, and shelf-life data, ensuring safety while minimizing material use. - Electronics and Consumer Goods

AI predicts the safest yet smallest packaging configuration to reduce shipping costs without compromising product integrity. - Pharmaceuticals

AI systems ensure compliance by maintaining tamper-evident packaging while reducing redundant layers and material wastage. - E-commerce & Logistics

AI agents automatically optimize package dimensions based on the product and courier specifications, reducing dimensional weight charges.

In each case, AI in manufacturing operations bridges the gap between cost efficiency and sustainability — two of the biggest priorities in modern packaging.

Challenges in Implementing AI Packaging Optimization

While the advantages are clear, adopting AI systems in packaging does come with challenges:

- Data Fragmentation: Disconnected systems can slow down AI training.

- Integration Complexity: Legacy equipment may not support AI directly.

- Initial Investment: AI infrastructure and model training require upfront costs.

- Workforce Training: Teams need to adapt to AI-driven workflows.

However, these challenges can be minimized by collaborating with a reliable AI agents development company that handles end-to-end deployment — from data collection to AI lifecycle management.

How Bluebash Helps Overcome These Challenges?

Bluebash provides a structured and scalable approach to implementing AI packaging optimization across manufacturing environments. As a full-cycle AI agents development company, Bluebash ensures that the transition from traditional packaging systems to intelligent automation is seamless, cost-effective, and sustainable.

- Solving Data Fragmentation with Unified AI Data Pipelines

Bluebash develops centralized AI data pipelines that collect, clean, and standardize information from multiple systems — including ERP, MES, and IoT sensors. This ensures that AI models receive consistent, high-quality data for accurate predictions and continuous learning. - Seamless Integration with Legacy Equipment

Manufacturers often face difficulties integrating AI with legacy systems. Bluebash bridges this gap by using custom middleware and API connectors that link existing machinery and software platforms to modern AI systems. This approach allows companies to leverage AI in manufacturing operations without a complete system overhaul. - Cost-Efficient AI Implementation

To make AI adoption accessible, Bluebash follows a modular implementation strategy — starting with pilot projects and scaling as ROI becomes evident. This phased approach minimizes risk and ensures measurable gains before full-scale deployment. - Empowering Workforce with AI Training & Support

Bluebash doesn’t just implement AI — it empowers your workforce to use it effectively. Through hands-on training, real-time dashboards, and user-friendly interfaces, Bluebash helps teams interpret insights from AI-powered packaging optimization tools and make data-driven decisions confidently. - Continuous AI Optimization and Lifecycle Management

Post-deployment, Bluebash continuously monitors model performance and production metrics. Their AI agents for packaging optimization learn and adapt over time, ensuring sustained improvement in efficiency, waste reduction, and packaging performance.

Future of AI-Powered Packaging Optimization

The future of AI packaging optimization will move beyond design and material efficiency into predictive sustainability. With the integration of digital twins and multi-agent systems, AI will simulate entire packaging lifecycles — from material sourcing to end-of-life recycling — enabling circular manufacturing ecosystems.

Emerging trends include:

- Real-time packaging adaptation based on product changes.

- Sustainability scoring integrated into packaging lines.

- AI-driven robotic packaging lines with autonomous adjustment capabilities.

- Predictive analytics for supply chain-linked packaging optimization.

Manufacturers adopting AI-powered packaging optimization today are not only improving operational efficiency but also future-proofing against evolving environmental and economic demands.

Conclusion: Streamline, Save, and Sustain with AI

Implementing AI packaging optimization in manufacturing operations is more than a tech upgrade — it’s a strategic move toward smarter, leaner, and greener production. From material efficiency to logistics optimization, AI agents deliver measurable ROI and long-term sustainability.

If you’re looking to reduce waste, improve packaging performance, and gain real-time insights into your packaging workflow, partnering with an experienced AI agents development company like Bluebash can help you make that transformation seamless and scalable.

FAQ's

- What is AI packaging optimization?

AI packaging optimization uses machine learning and data analytics to improve packaging design, reduce material waste, and streamline manufacturing operations. - How do AI agents help in packaging optimization?

AI agents analyze data from production, materials, and logistics to recommend cost-efficient, sustainable packaging solutions in real time. - Can AI packaging optimization integrate with existing systems?

Yes. With the right AI agents development company like Bluebash, AI tools can seamlessly connect with ERP, MES, and PLC systems. - What benefits can manufacturers expect from AI packaging optimization?

Manufacturers can achieve reduced material usage, faster packaging times, lower costs, and improved sustainability metrics. - Why choose Bluebash for AI packaging optimization?

Bluebash offers end-to-end AI solutions tailored for manufacturing—ensuring smooth integration, continuous optimization, and measurable ROI.